Automated Solutions for Process Monitoring and Control Requirements

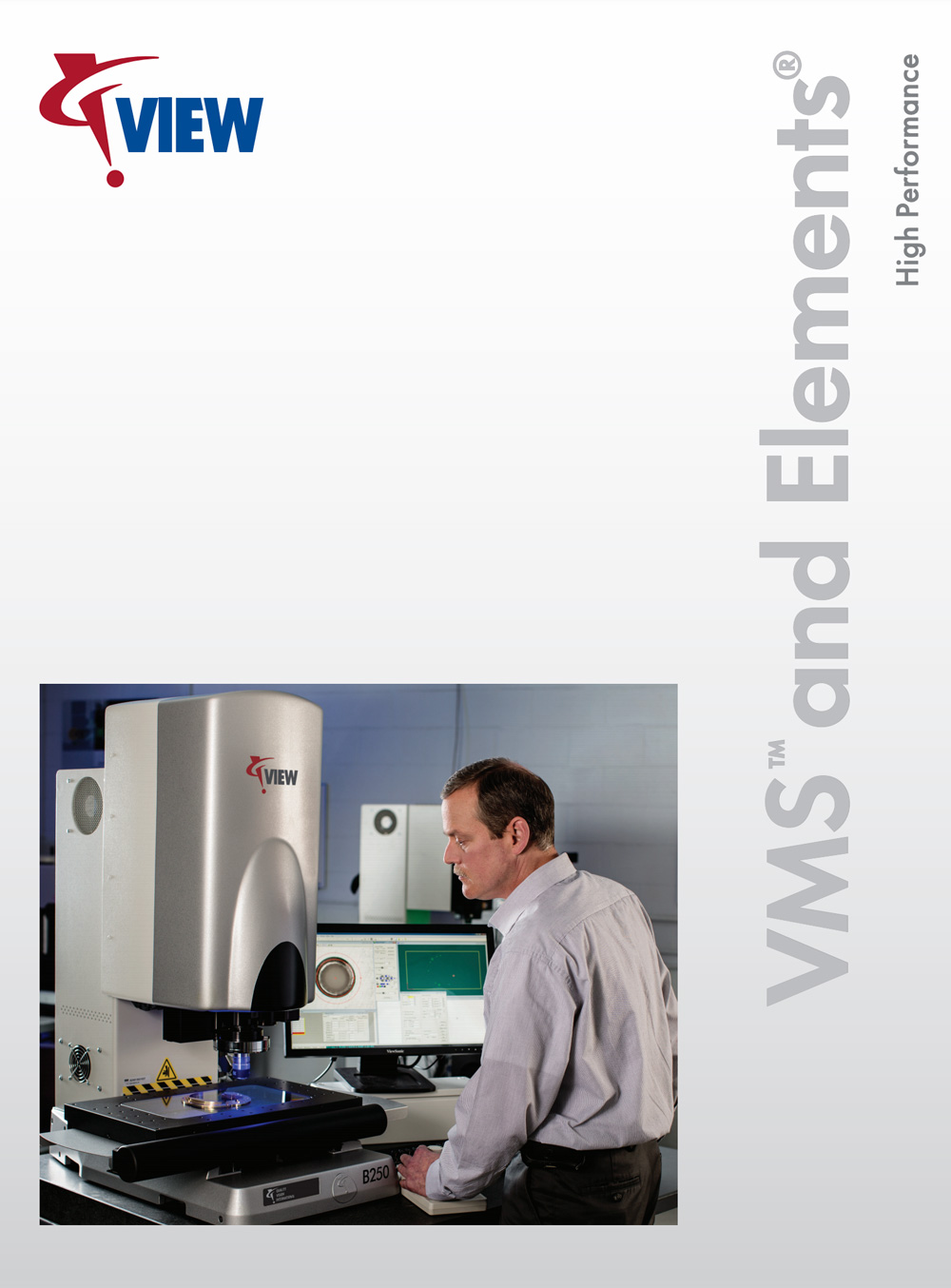

VIEW Metrology Software (VMS™) presents feature-oriented programming in a standard Windows® interface, effectively bridging the gap between the Q/A lab and the production environment.

VMS provides extensive capabilities that allow the software to easily handle difficult lighting conditions, weak edges, and part-to-part variability. Advanced features such as Step and Repeat, Local Alignments, CAD Import, and Part Family Programming make complex part layouts easy to set up. VMS also provides a host of customizable features, such as programming variables, branching and looping, and “If then, Else” type statements to make the inspection process adaptable to your quality monitoring needs.

VMS provides measurement data is formats that are compatible with external databases and statistical analysis software. VMS is directly integrated with Evolve SPC (ESPC). ESPC provides the ability to store measured data which is selectively retrievable, real-time Process Control, Gage Reproducibility and Repeatability Studies, descriptive and inferential statistics, and custom reporting.

Easy to Use for Programmer and Floor Operator Alike

For the engineer, the feature-rich editing mode in VMS provides all of the functionality and flexibility needed to design highly accurate and repeatable metrology applications for the most demanding of measurement challenges.

For the production floor operator, the runtime interface delivers intuitive ease-of-use and minimizes learning curves while maximizing accuracy and productivity. Combined with VIEW’s VIP run-time interface package, you can create a simple, operator-friendly control panel with automatic data handling and SPC.

Unlike systems that trade off high-end functionality to deliver so-called “ease-of-use,” the VMS programming environment and simple run-time operation combine uncompromising programmability with performance-optimized ease of operation.

FEATURES

Edge Finding

- Finder Optimization (using the Teach button) can be used to automatically adjust advanced parameters such as form, strength, contrast, and other parameters to more reliably find edges under difficult conditions.

- Automatic light settings are now available to dynamically adjust the programmed light settings to compensate for the part surface reflectivity variations or the lighting differences among multiple inspection systems.

- Blob Filtering makes the blob finder more reliable in cases where there are many small entities in the field of view, such as grain or dust, which could be mistaken for a blob feature.

- Area Multi-Focus allows creating a 3-D profile of a feature within the field of view using a single video focus sequence.

Programming Aids

- Libraries have been added so that sub-routines for frequently used measurements or situations can be saved and readily implemented in new part programs.

- Data driven expressions can be defined to implement the “part family” programming capability of VMS.

- CAD Import / Auto Step Create has been implemented so that when a CAD file is imported, the measurement steps for the selected features of the CAD model are generated automatically with a single mouse click.

Data Management

- Automatic Point Coordinates output is now available, allowing “point cloud” data to be exported to other feature geometry construction packages (for profile measurements) using the COM/DDE methods of the Windows operating system.

- Excel output allows measurement results to be easily exported to Microsoft Excel®.

- Security features have been added to enable access to certain features to be limited by password. For example, access to program edit, save, and delete functions can be restricted, while still allowing programs to be loaded and run.