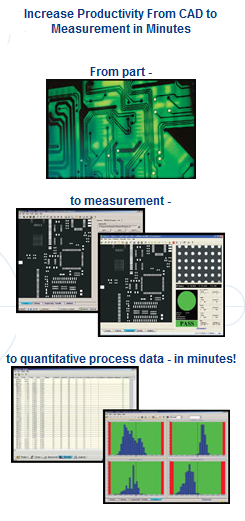

CAD-to-Measure Software for Electronic Assemblies & Packages

VIEW’s Elements® software is designed specifically for precision measurement of circuit board and electronic assemblies in a high mix manufacturing environment. Elements uses a library of pre-configured SMT component algorithms to automatically create measurement routines from CAD Files. No time-consuming programming is required – simply import the CAD file and the routine is ready for measurement. Elements allows part changeovers to be set up in minutes, not hours.

Elements is fast. It optimizes the inspection sequence, enabling hundreds or thousands of features to be measured in minutes. Elements is also used to enable CAD-to-measure translation for entire families of similar parts.

Elements is made up of individual software modules, each targeting a specific measurement need within the electronic assembly process:

- Stencil/Screen – Measure incoming and production stencils (after cleaning) to ensure the dimensional integrity of apertures and to identify blockages.

- PCB – Measure holes, pads, and vias on multi-layer printed circuit boards. Also measure layer registration, a critical concern for fabricators.

- Solder Paste – Measure solder paste registration with respect to pads on the PCB. Solder paste volume and epoxy glue dot registration are quickly measured.

- Component Placement – Measure slugs on glass to verify placement machine accuracy according to IPC 9850. Also measure the position and orientation of actual components on glass, on boards, and in paste.

- Leadframe – Measure leadframe features including lead size, position, angle, tilt, twist, and coplanarity.

- Component Package – Measure wirebond features including ball diameter (or wedge major/minor axes) and bond-to-pad registration. Measure package features (of QFPs, BGAs, CSPs, Flip Chips) including lead (or ball) position, height, spacing, device coplanarity, and seating plane.

A VIEW Benchmark or Summit system with Elements Software provides three main advantages:

- It is one piece of capital equipment that is versatile enough to make precise measurements at many points (incoming stencils, incoming PCBs, incoming components, the solder paste process, and the component placement process) throughout the SMT assembly process.

- It dramatically reduces set-up time by importing CAD files and using this data to automatically generate measurement programs. This capability means efficient metrology in low-volume / high-mix manufacturing environments.

- It helps improve production metrology practices without increasing the need for dedicated programming / metrology personnel.